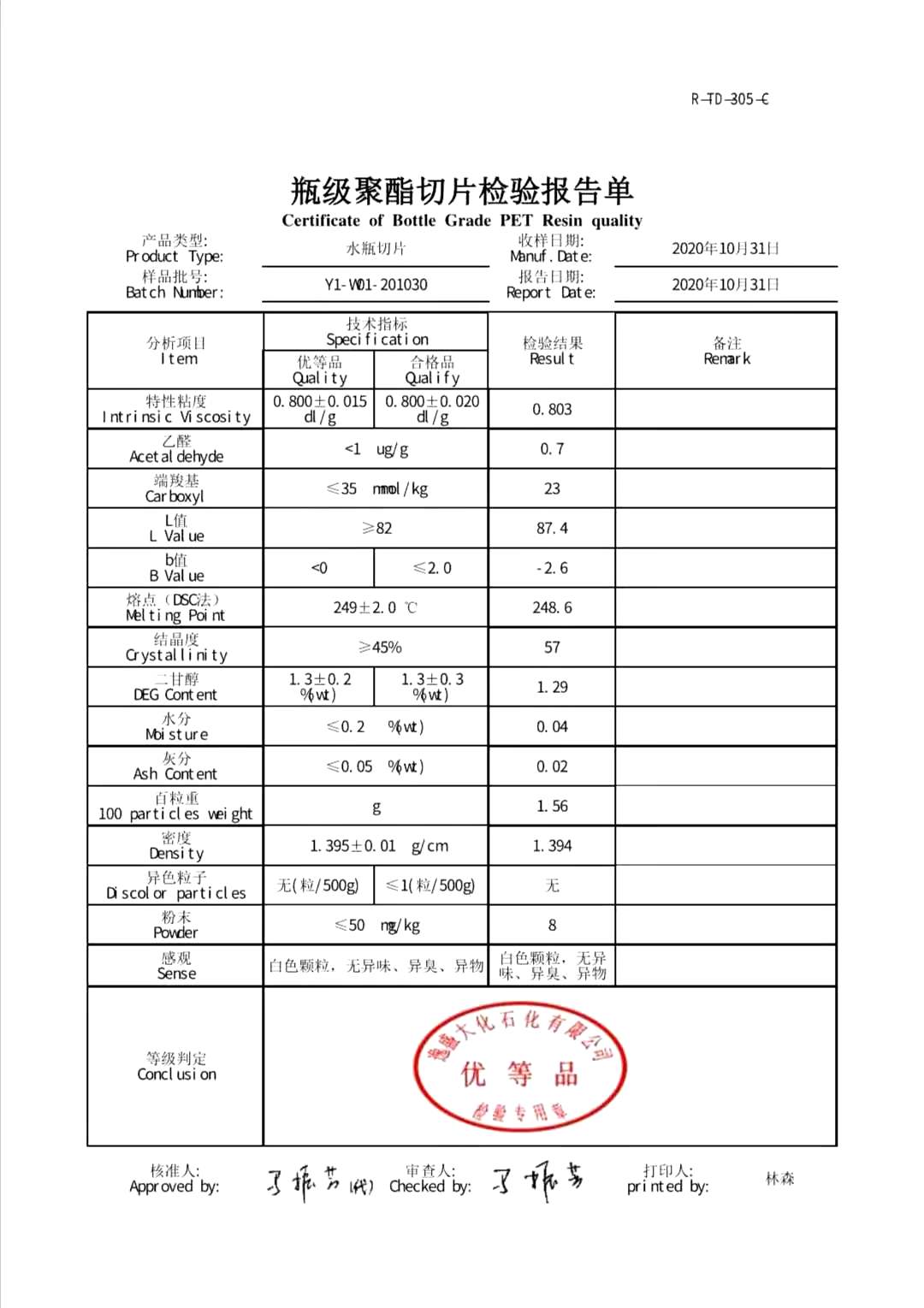

Yisheng Dahua Bottle Grade PET Chips IV0.80 for Food and Beverage Packaging

Executive Summary

Yisheng Dahua Bottle Grade PET Chips IV0.80 represent a breakthrough in food and beverage packaging materials, combining precision engineering with eco-conscious manufacturing. Designed for high-speed production lines, this polymer resin delivers unmatched clarity, durability, and processability while meeting the stringent hygiene and safety standards of global food regulators. With an intrinsic viscosity (IV) of 0.80 dl/g, it strikes an optimal balance between melt flow efficiency and end-product structural integrity, making it ideal for lightweight containers, hot-fill applications, and carbonated beverage bottles.

Technical Specifications

- Intrinsic Viscosity (IV): 0.80 dl/g (±0.015 tolerance)

- Carboxyl End Groups (CEG): ≤20 mmol/kg

- Acetaldehyde (AA) Content: ≤1.2 ppm (preform grade)

- Melting Point: 245–252°C

- Moisture Content: ≤0.3% (vacuum-dried)

- Color Values:

- L* Brightness: ≥85

- b* Yellowness Index: ≤1.8

- Density: 1.38–1.40 g/cm³

- Thermal Stability: ΔIV ≤0.02 dl/g after 8hrs @ 170°C

Certified to FDA 21 CFR 177.1630, EU Regulation No. 10/2011, and China GB 4806.7-2016 for direct food contact.

Key Performance Advantages

1. Superior Processability

The IV0.80 formulation enables:

- 18–22% faster cycle times compared to standard PET resins due to optimized melt viscosity.

- Low-energy processing with extrusion temperatures reduced to 270–285°C (vs. 290°C for conventional PET).

- Exceptional shear stability, minimizing viscosity drop (<5%) during high-speed injection molding.

- Anti-caking additives ensure consistent pellet flow in automated feeding systems.

2. Enhanced Product Safety

- Ultra-low acetaldehyde regeneration: ≤3 ppm in final containers (meets infant formula packaging standards).

- Non-toxic catalyst system (antimony content <220 ppm).

- Passes NSF/ANSI 61 certification for potable water containers.

3. Mechanical Robustness

- Tensile Strength: 50–65 MPa (post-stretch blow molding).

- Top Load Resistance: ≥130 kgf for 1.5L carbonated beverage bottles.

- Impact Resistance: Survives 1.8m vertical drops (500ml bottle, -20°C conditioned).

- Creep Resistance: <0.3% deformation under 250 psi/72hrs.

4. Optical Purity

- Haze: ≤1.2% (ASTM D1003).

- Light Transmission: 92–94% across 380–780nm spectrum.

- UV Barrier Options: Customizable with <5% transmittance at 300–360nm.

5. Sustainability Edge

- 100% Recyclable: Compatible with mechanical recycling (up to 7 cycles with <15% IV loss).

- rPET Blending: Stable processing with 25–40% post-consumer recycled content.

- Carbon Footprint: 2.1 kg CO₂e/kg (23% lower than industry average).

- Blue Angel & EuCertPlast Certified for eco-friendly production.

Manufacturing Excellence

Produced via Yisheng Dahua’s proprietary Dual-Stage Solid-State Polycondensation (DSSP) technology:

- Melt Phase Polycondensation:

- Continuous reactor design with titanium-based catalysts.

- Precise IV control via real-time viscometry.

- Solid-State Enhancement:

- Crystallization at 150–160°C under nitrogen atmosphere.

- Oligomer content reduced to ≤0.45%.

- Pelletization:

- Underwater strand cutting with anti-static surface treatment.

- 100% metal-detected and laser-sorted for purity.

Quality Assurance Protocols

- Batch Tracking: RFID-enabled lot traceability from raw materials to shipment.

- Testing Regimen:

- Daily GC-MS analysis for VOC contaminants.

- Weekly ISO 1133 melt flow rate verification.

- Monthly third-party migration tests (10% ethanol, 3% acetic acid simulants).

- Shelf Life: 18 months in moisture-proof packaging (<40% RH, 25°C storage).

Applications Across Industries

1. Carbonated Drinks

- Withstands internal pressure up to 5.5 bar.

- CO₂ permeability: ≤0.6 cm³·mm/m²·day·atm.

2. Juices & Dairy Products

- Oxygen barrier: ≤0.12 cm³·mm/m²·day·atm.

- Resistant to enzymatic degradation (pH 2.0–8.5).

3. Edible Oil Containers

- Hydrolysis resistance: ≤0.03% IV loss after 90 days @ 40°C/75% RH.

- UV-blocking variants prevent lipid oxidation.

4. Hot-Fill Packaging

- Thermal stability: 85°C filling temperature with <1% shrinkage.

- Maintains clarity after 12-month shelf life.

5. Lightweight Bottles

- Achieves 10.5g preform weight for 500ml water bottles (21% lighter than standard designs).

Sustainability Commitments

- Zero Process Waste: 99.8% closed-loop solvent recovery system.

- Renewable Energy: 35% of production powered by solar/wind.

- Take-Back Program: Partners with 200+ global recycling facilities.

Customization Options

- Additive Packages:

- Oxygen scavengers (0.08–0.12% active uptake).

- Anti-fog agents for refrigerated displays.

- Flame retardants (UL94 V-2 compliant).

- Color Solutions:

- Pantone-matched pre-compounded resins.

- Transparent, frosted, or opaque finishes.

Supply Chain Advantages

- Global Stock: 15 strategic warehouses across Asia, Europe, and North America.

- Packaging: 25kg multi-layer aluminized bags with resealable zippers.

- Lead Time: 10–15 days for standard orders; expedited 72hr air freight available.

Market Validation

- Adopted by 5 top-tier beverage brands for 250ml–3L container production.

- Awarded 2023 Plastics Innovation Prize for energy-efficient processing.

- Enables 17% cost reduction per container through downgauging and faster cycles.

Technical Support Ecosystem

- 24/7 multilingual customer service.

- On-site processing troubleshooting.

- Free trial batches with performance analytics.

- Annual PET Processing Masterclass webinar series.

Future-Forward Innovations

- Bio-Attributed PET: 30% biomass-derived monomers (ISCC PLUS certified).

- Active Barrier Technology: Embedded oxygen-absorbing nanoparticles.

- Smart Tagging: In-resin fluorescent markers for enhanced recycling sorting.

Conclusion

Yisheng Dahua Bottle Grade PET Chips IV0.80 redefine the benchmarks for packaging materials, merging operational efficiency with uncompromising safety and environmental stewardship. From ultra-clear mineral water bottles to robust hot-fill tomato sauce containers, this resin empowers brands to meet evolving consumer demands while future-proofing their sustainability commitments. Backed by Yisheng Dahua’s 25 years of polymer expertise, it stands as the intelligent choice for manufacturers prioritizing quality, compliance, and circular economy principles in a competitive global market.

TDD-Global.com is a professional China chemical B2B marketplace operated by IBI Company, dedicated to promoting global communication, business negotiation, and market expansion in the chemical industry. With a strong network of China chemical product suppliers and international buyers, TDD-Global creates a dynamic and efficient platform for sourcing, trading, and cooperation.

Under the brand name TUDUODUO, TDD-Global has built a trusted reputation among suppliers and buyers in sectors such as fine chemicals, raw materials, industrial additives, and advanced chemical solutions. We offer a wide range of services including product listing, online promotion, supply chain solutions, and international marketing support.

Our platform connects hundreds of verified China chemical suppliers with buyers worldwide, fostering transparent transactions, better business opportunities, and high-value partnerships. Whether you are looking for bulk commodities, specialty chemicals, or customized procurement services, TDD-Global is your go-to platform.

Driven by the innovative spirit of IBI Company, we are committed to building a smarter, faster, and more reliable global chemical trade ecosystem.

If you are interested in cooperation, strategic partnerships, or customized chemical sourcing, please feel free to contact us. Let's shape the future of the chemical industry together!

| Company Name | Beijing TDD E-commerce Co., Ltd | البلد / المنطقة | China |

| نوع الأعمال | متجر عبر الإنترنت | حجم الشركة | 2000 |

| تأسس | December 18, 2014 | ||

| العنوان | Building No.3, Area 6, No.188, West of South Forth Ring Rd, Beijing, China | ||

| المنتجات الرئيسية | راتنج PVC ، PP ، PE ، Pet ، ثاني أكسيد التيتانيوم ، Pigment ، إطارات السيارات | ||

| International Commercial Terms(Incoterms): | FOB, CFR, CIF, FCA | ||

| Terms of Payment: | LC, T/T, D/P | ||

| Average Lead Time: | Peak Season Lead Time: one month, Off Season Lead Time: within 15 workdays | ||

| Number of Foreign Trading Staff: | 20~40 People | ||

| Main Markets: | Southeast Asia, Africa, Mid East | ||

| Nearest Port: | Tianjin,Qingdao,Shanghai | ||

| Import & Export Mode: | Have Own Export License | ||